BƠM LY TÂM THỰC PHẨM – MÁY BƠM LY TÂM VI SINH HYGIENIC CENTRIFUGAL PUMPS – JAPAN PRODUCT MADE IN CHINA | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

VVM-XD-N SERIES

Hygienic Centrifugal Pumps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

HYGIENIC CENTRIFUGAL PUMPS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

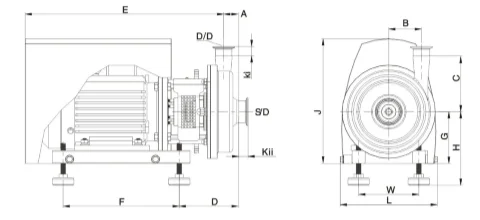

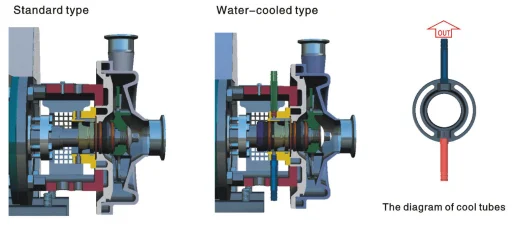

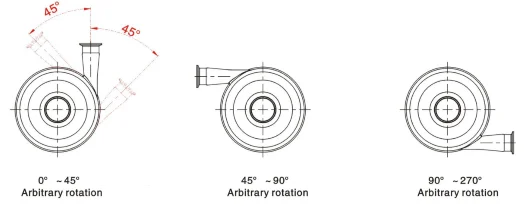

Summary Pump will transfer motor’s mechanical energy or other types of energy to increase pumping fluid’s energy (e.g pressure, potential and kinetic). The pump can be divided into two main types, dynamic and positive displacement. Centrifugal pump belongs to the dynamic pump. Centrifugal pumps is a mechanical device used for many purposes or applications. It has varieties of models and specifications due to the different of applications, performance parameters and transmission medium. Our company’s new sterile pump VVM-XD-N series are very high efficient and economical ones. They are chemically stable and fully applied to today’s world of environmental and food safety concern. All sealing, impeller, mechanical reducers the pollution risk to minimum for both products and environment. Working principle When the motor drives the impeller to rotate, liquid will impeller to do circular motion, At the same time centrifugal force will move fluid from the center of impeller. The liquid gained energy of pressure and speed from the impeller. This will create a lower pressure (compared to sanction surface) spot in the center of impeller, then liquid can continucusly be inhaled and moved in centain pressure. Application It can be widely used in food beer, beverage, dairy products, pharmaceutical and other industries. It can transport liquid with low and middle viscosity (viscosity < 300CP). Also, it can transport coeeosive liquid with low concentration. Design Standard VVM-SD-N pump series include: a standard motor, pump shaft, expansion connector, bracket, rear cover, impeller. Pump head amd mechanical sea;/ VVM-XD-N pump series meets European sanitary standard. The pump dead can rotate 45 with a vertical drain. So they are applicable to the design of CIP and SIP. It designed with arc transition and cleanable shaft sealing. VVM-XD-N series pumps applicable for hygienic uses have stainless motor casing cover, equipped with four stainless steel shockproof adjusting supporting foot. Design Parameter Pump with stand pressure resistant: 10kg/cm Mechanical seals pressure resistant: 5kg/cm (suction pressure) Use temperature: -10 to 120 Surface treatment: mirror polished surface. The outer furface of pickling or sandblasting Material: The parts in contact with liquid stainless steel 304 or 316L stainless steel, the other parts 304 stainless steel Seal: EPDM rubber Motor Specifications: 50Hz: 0.75 – 1.1 – 1.5 – 2.2 – 3 – 4 - 5.5 – 7.5 -11 – 15 -18.5 – 22 -30Kw. 60Hz: 0.9 – 1.3 – 1.75 – 2.5 – 3.5 – 4.6 – 8.6 – 12.5 – 17 – 21 – 25 – 35Kw

Mechanical seal Since the hygienic requirements í essential, XD-N pump is in line with European standards. All pumps are equipped with suitable seals for the hygienic requirements. It is particularly easy to refit with dual mechanical seal or water rinse function, In addition, it has the following advantages: · Good mechanical stability, mechanical gravity fall, seal service life can be greatly prolonged. · All pump seals are pressure balanced type. · Double shaft seal can be easily installed only need two same shaft seals. · Easy removal: removing the back cover and impeller, you can quickly replace the shaft seal. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

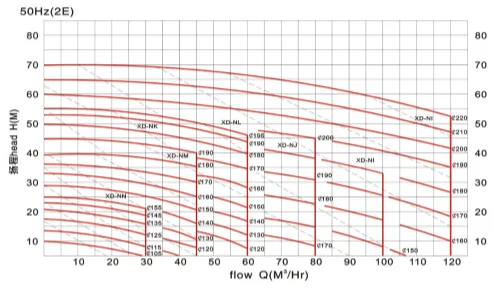

Characteristic chart ISO2548 Q8% H6% Acceptable error: iso2548 Q8% H6%

General considerations for pump selection and use: Using pump within temperature that the mechanical seal is available. The performance parameters of the pump is based on water as the test object. If the nature of the liquid is different from water, our company need to redesign and confirm whether it is available. In this case please contact us. Caculation of lifting height and flow If the pressure loss evaluation in pipeline is too small, this will cause the pump power (flow) deficiency. If the pressure loss evaluation in pipeline is too small, this will cause the motor overload. Our suggestion is to calculate by the equivalent length of pipes and plus 5% margin to decide lifting height. The pump total head = discharge head – suction head When fluid has viscosity (above 10CP) we need to modify pump power. When the pipeline is inversely washed, please set the bypass since there would be large pressure loss and reverse rotation.

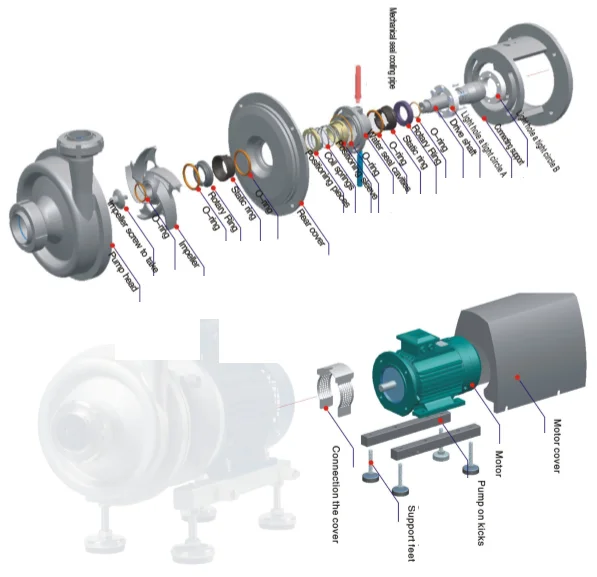

· Confirm the direction of rotarion before pump operation. Facing the pump, the impeller is counterclockwise. · Large capacity pump (above 5.5kw) frequent starting, stopping, affects all parts of the pump life, in this occasion, it is best to use step – down start. · Do not do idle running to avoid mechanical seal damage due to dry friction and high temperature. XD-N Series sanitary centrifugal pump structure exploded view | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1. Sports of basic types

2. Classification of motor poles

3. Classification of frequency

| 4. Motor types

| 5. Motor types

6. Types of mechanical seal

8. Pump inlet outlet connections in the form

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note: 1) With the increase of flow, head will be reduced relatively 2) Motor belongs to broadband motor, which is suitable for the voitage of 50Hz/60Hz. 3) If special ones are needed, please contact us, and the time of delivery would be adequately extended. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Đánh giá sản phẩm của chúng tôi