CENTRIFUGAL PUMPS SPECIFICATIONS 3M

SPECIFICATIONS 3LM

SPECIFICATIONS 3S

SPECIFICATIONS 3LS

SPECIFICATIONS 3P

SPECIFICATIONS 3LP

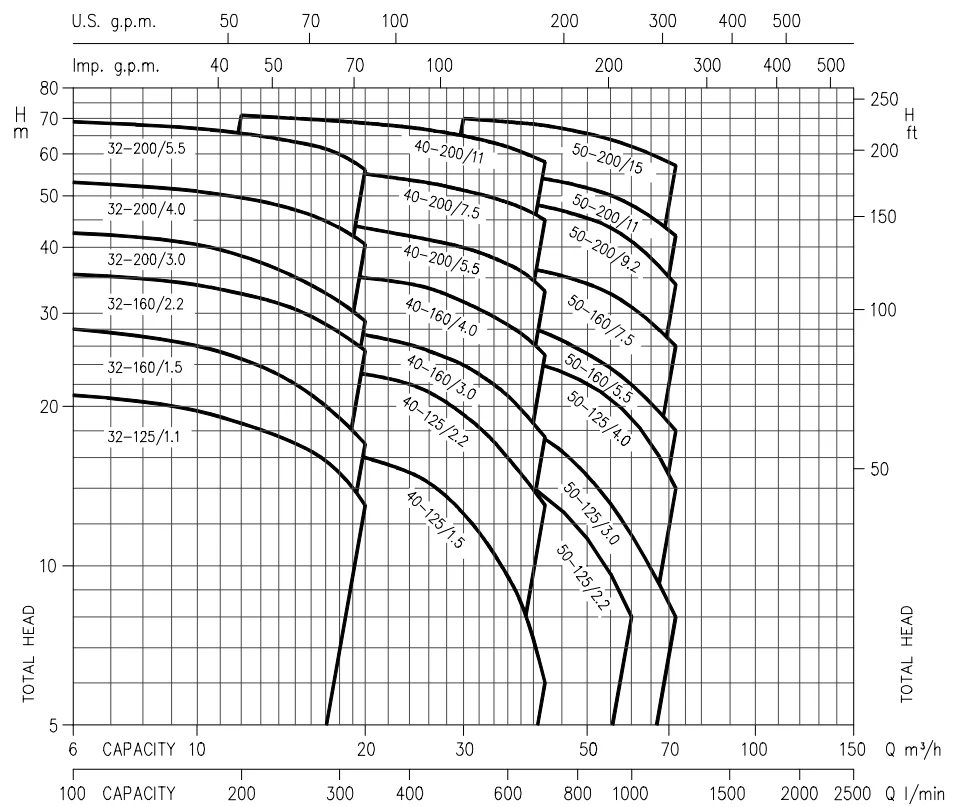

SELECTION CHART For pump 50-125/2,2 only 3M-3LM version

For pump 50-125/2,2 only 3M-3LM version.

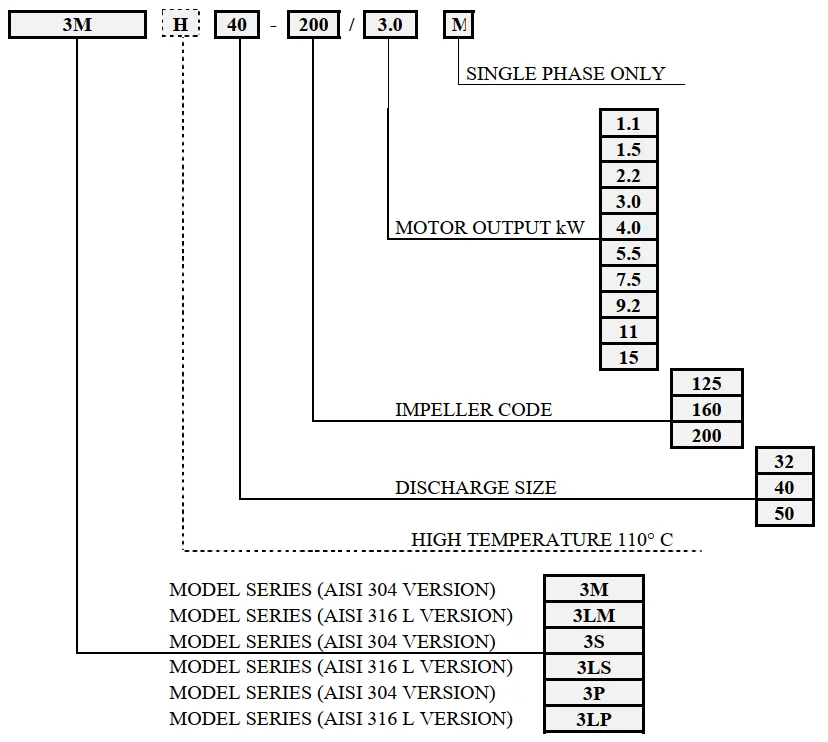

Type key

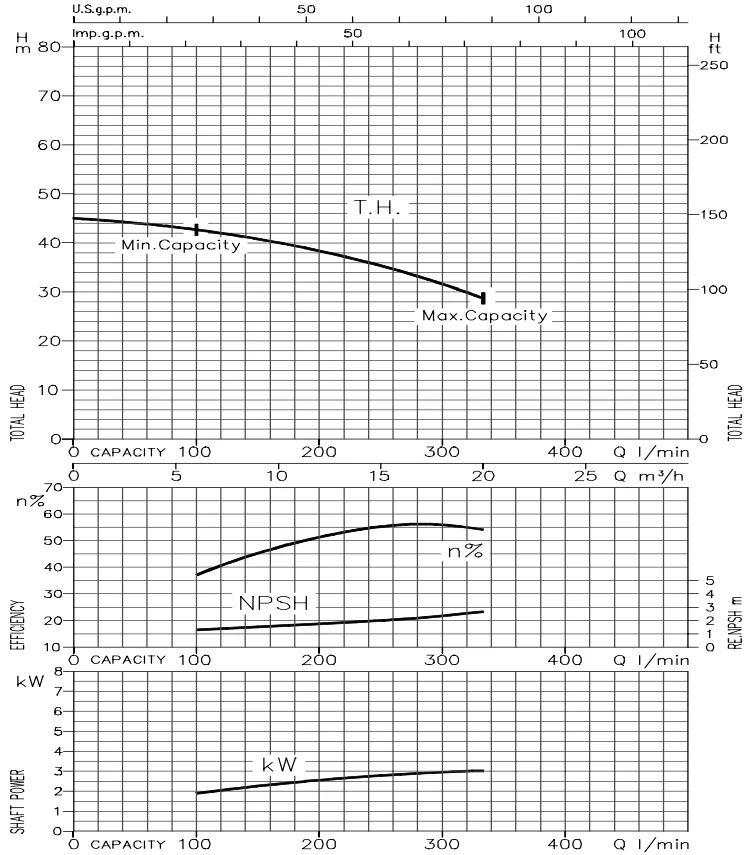

PERFORMANCE CURVES 32-125/1.1 (1.1 kW) - Impeller diameter = 133 Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

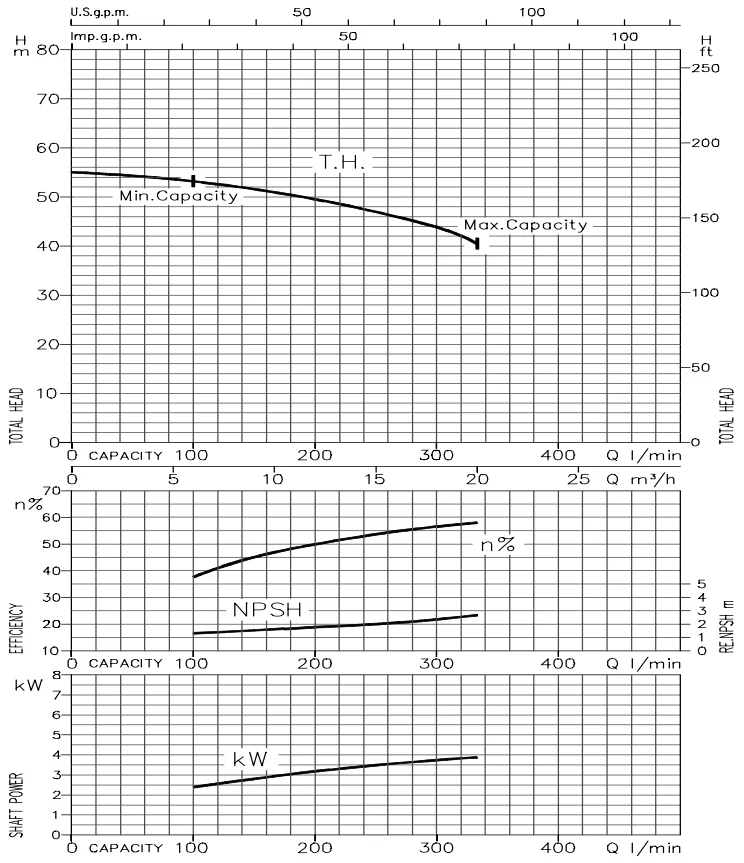

32-160/1.5 (1.5 kW) - Impeller diameter = 151

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

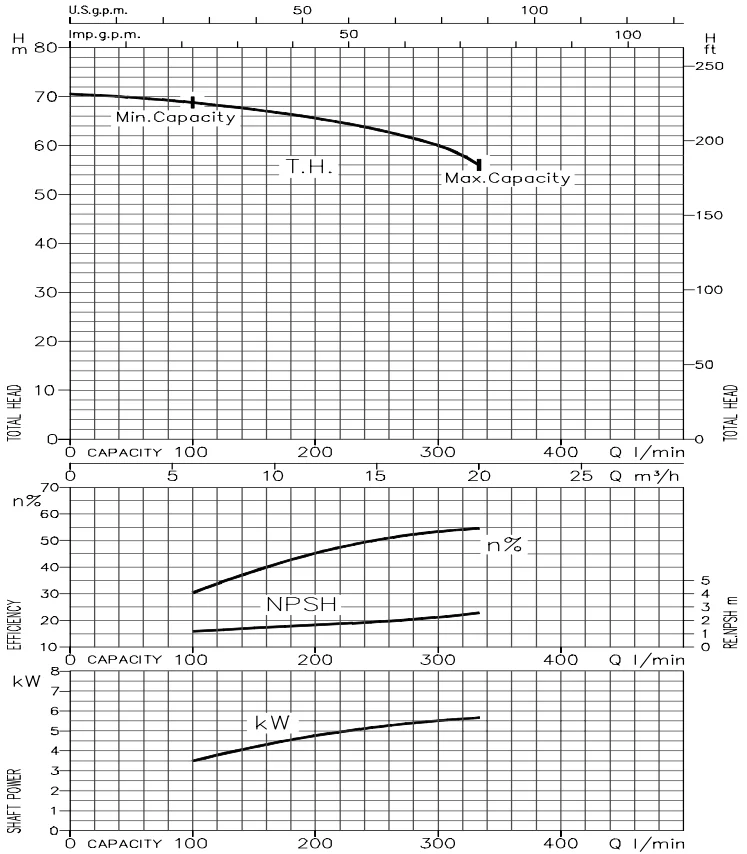

32-160/2.2 (2.2 kW) - Impeller diameter = 166

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

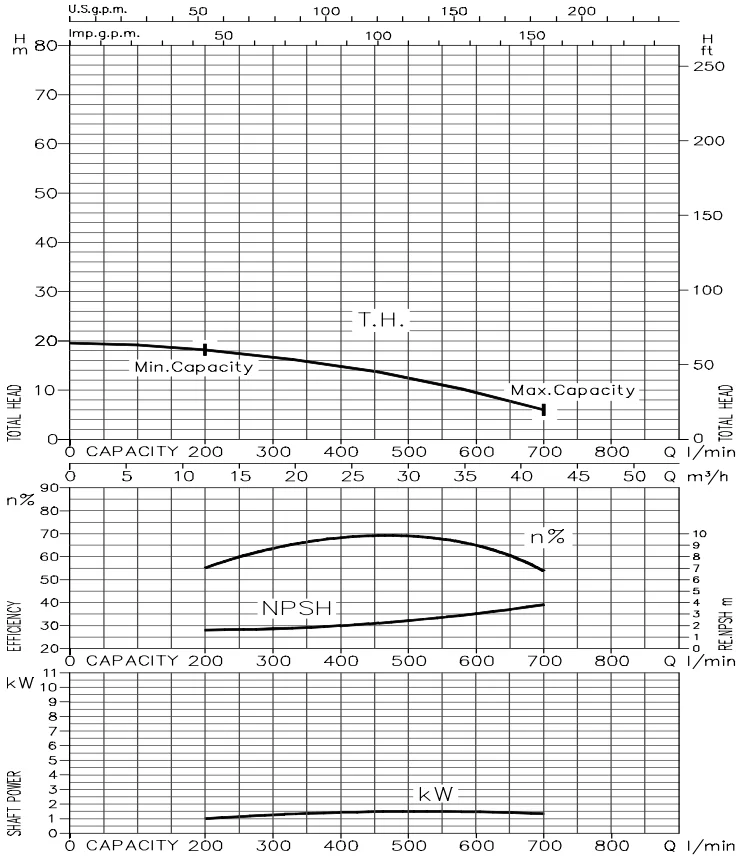

32-200/3.0 (3 kW) - Impeller diameter = 186

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

32-200/4.0 (4 kW) - Impeller diameter = 200

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

32-200/5.5 (5.5 kW) - Impeller diameter = 224

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

40-125/1.5 (1.5 kW) - Impeller diameter = 125

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

40-125/2.2 (2.2 kW) - Impeller diameter = 140

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

40-160/3.0 (3 kW) - Impeller diameter = 151

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

40-160/4.0 (4 kW) - Impeller diameter = 166

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

40-200/5.5 (5.5 kW) - Impeller diameter = 183

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

40-200/7.5 (7.5 kW) - Impeller diameter = 200

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

40-200/11 (11 kW) - Impeller diameter = 224 Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

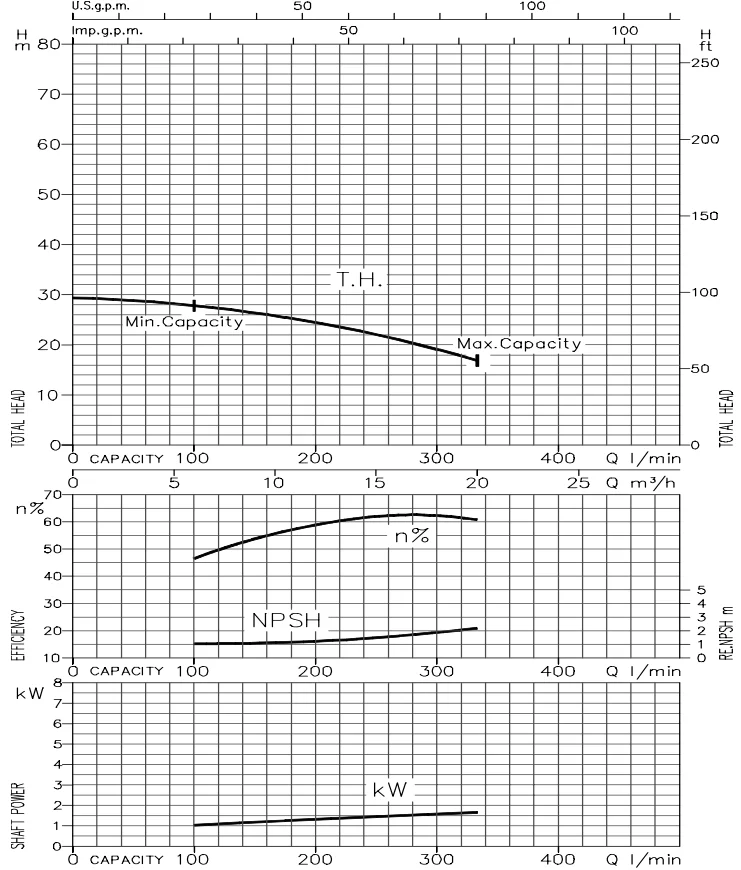

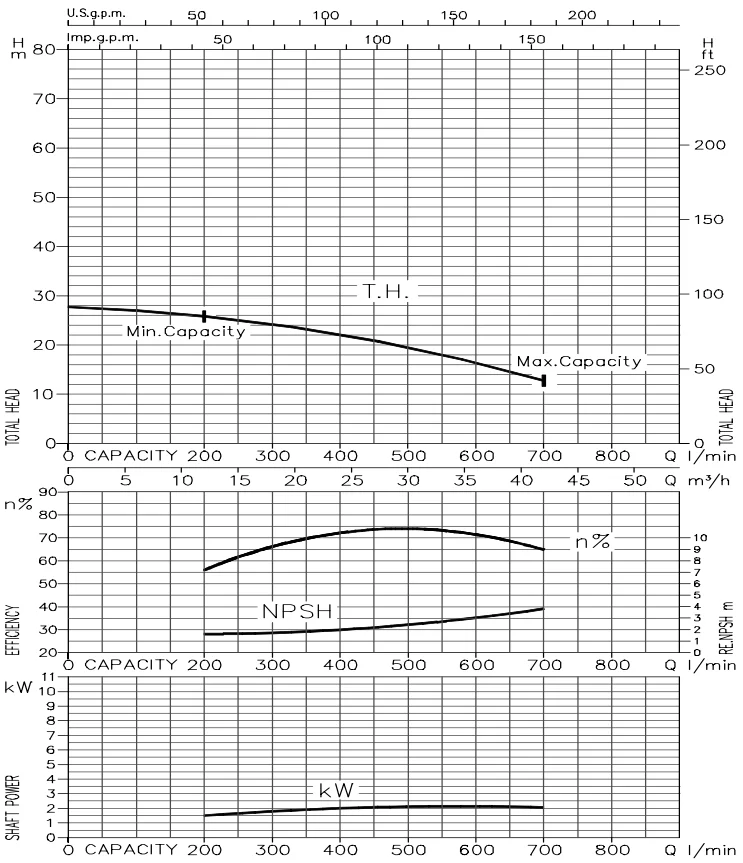

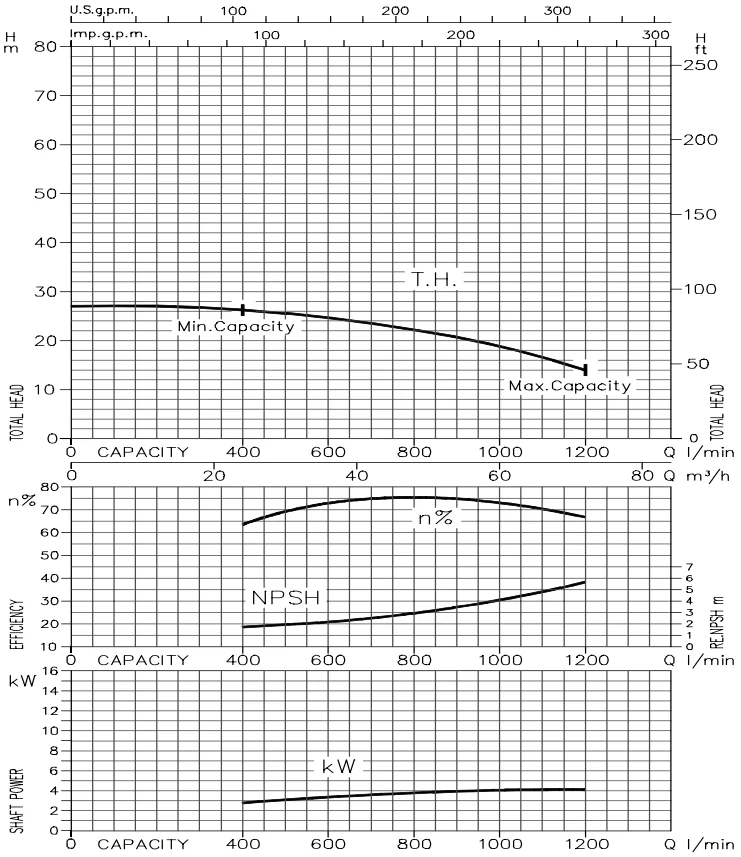

50-125/2.2 (2.2 kW) - Impeller diameter = 126

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

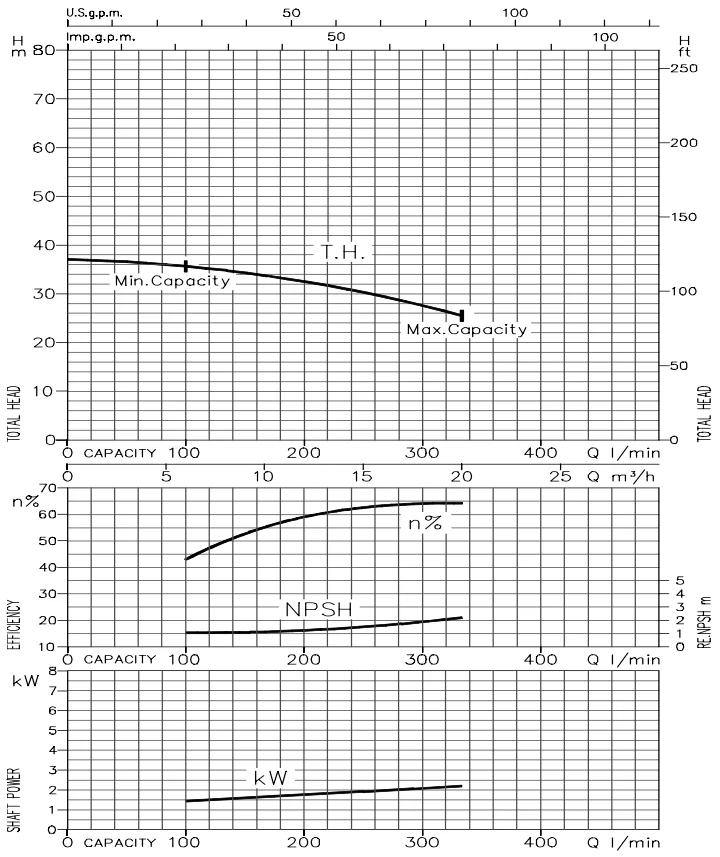

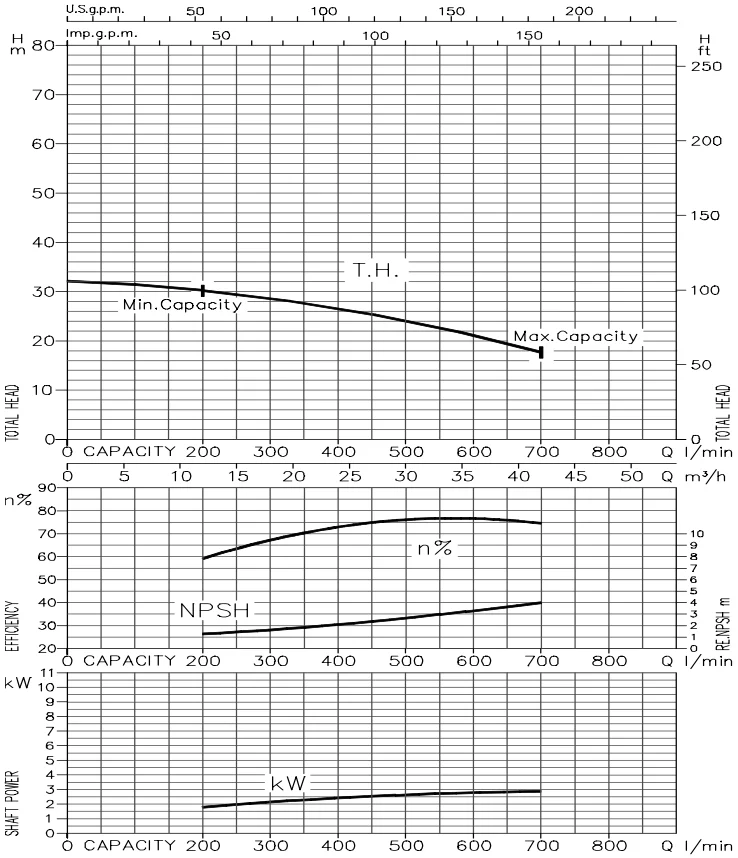

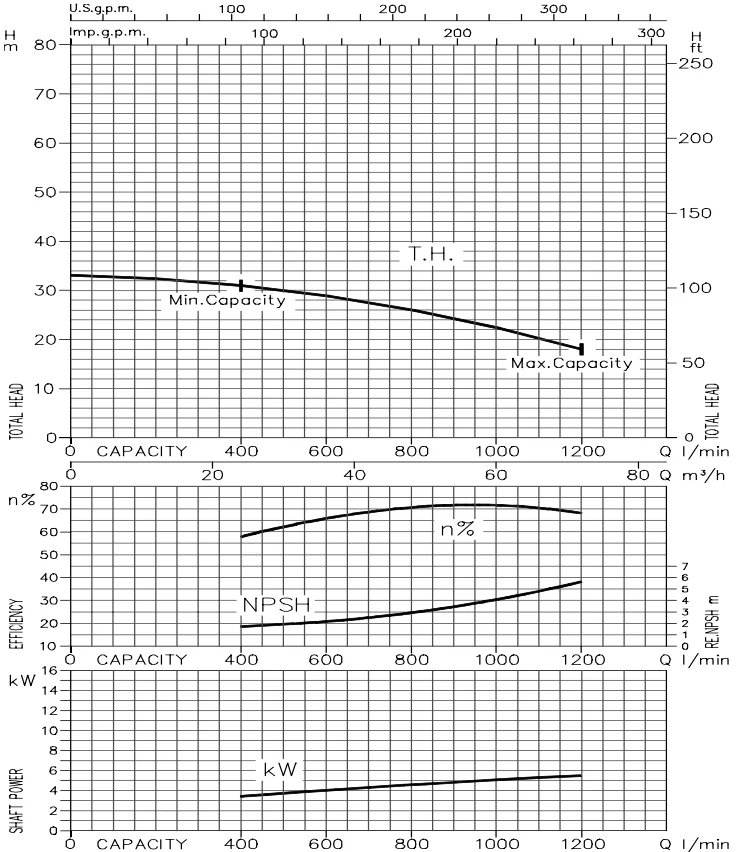

50-125/3.0 (3 kW) - Impeller diameter = 131 Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

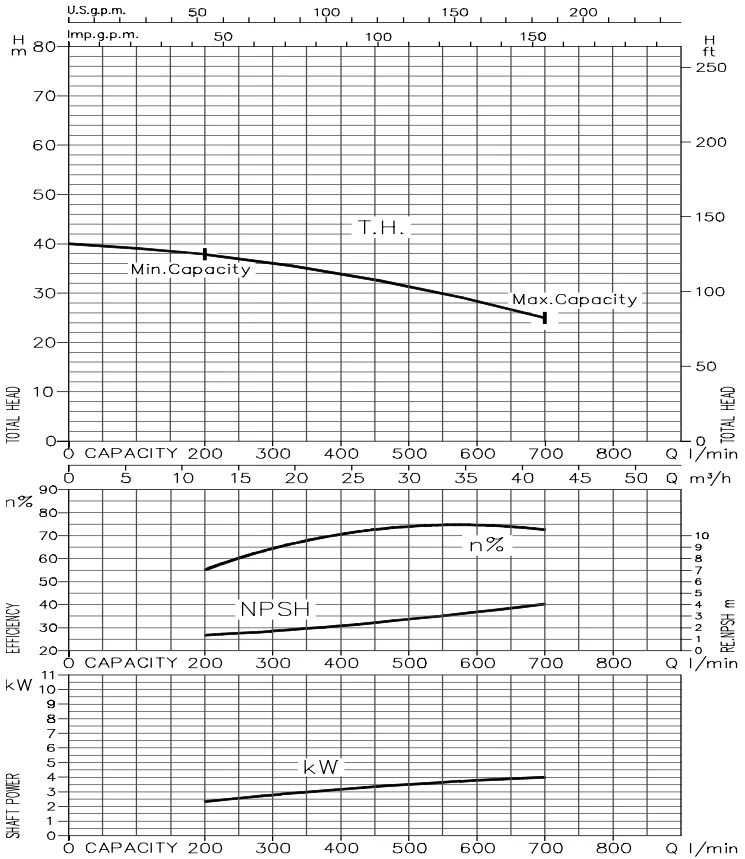

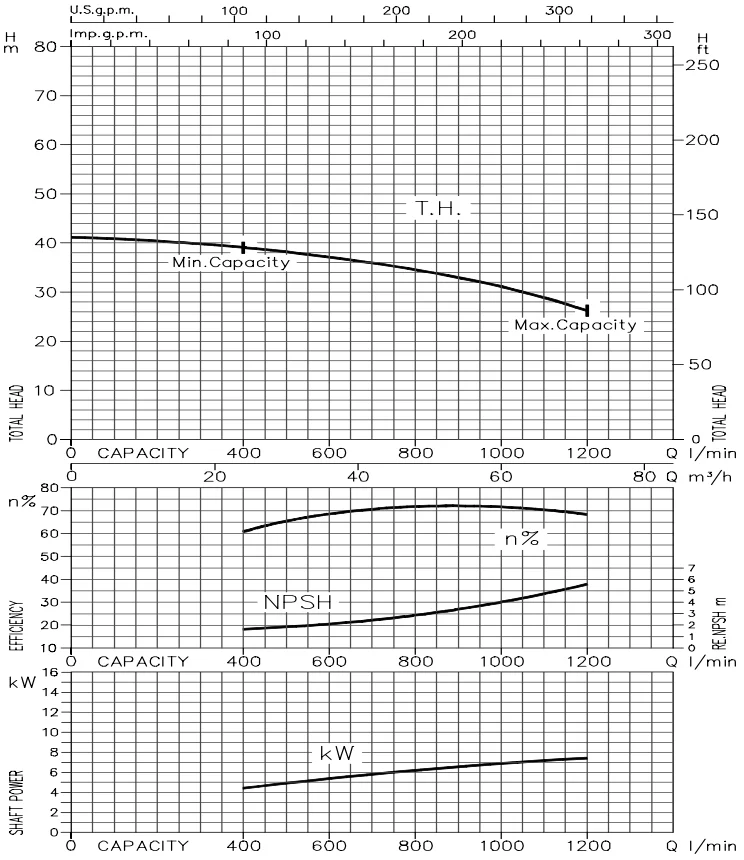

50-125/4.0 (4 kW) - Impeller diameter = 140 Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

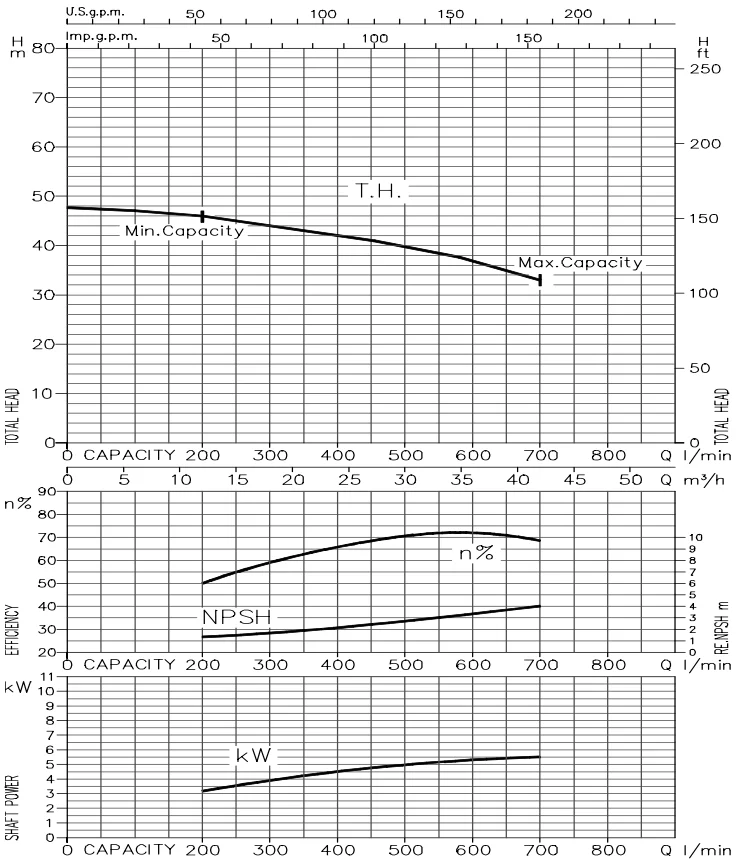

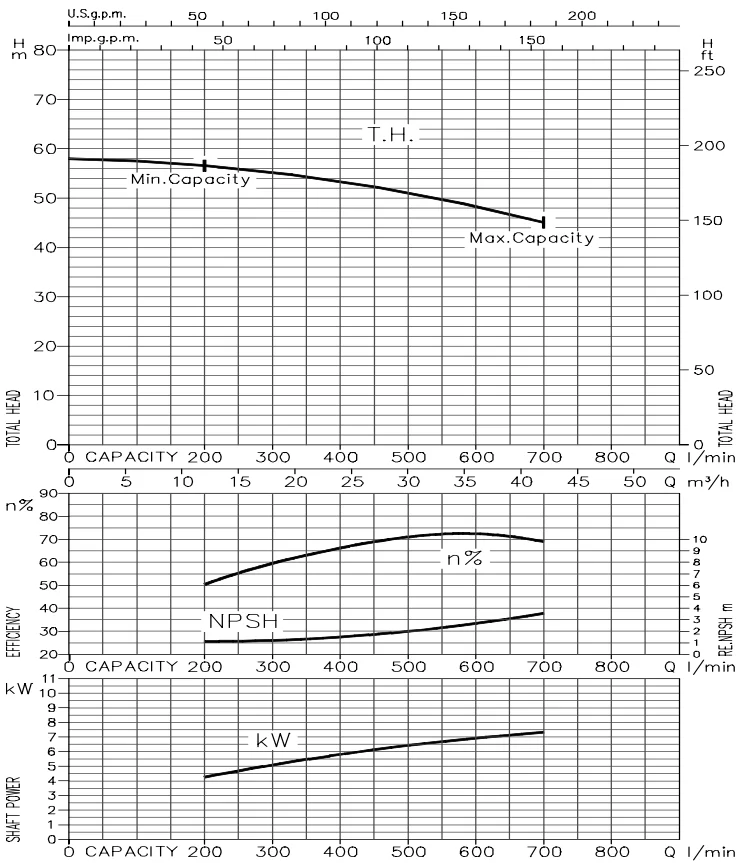

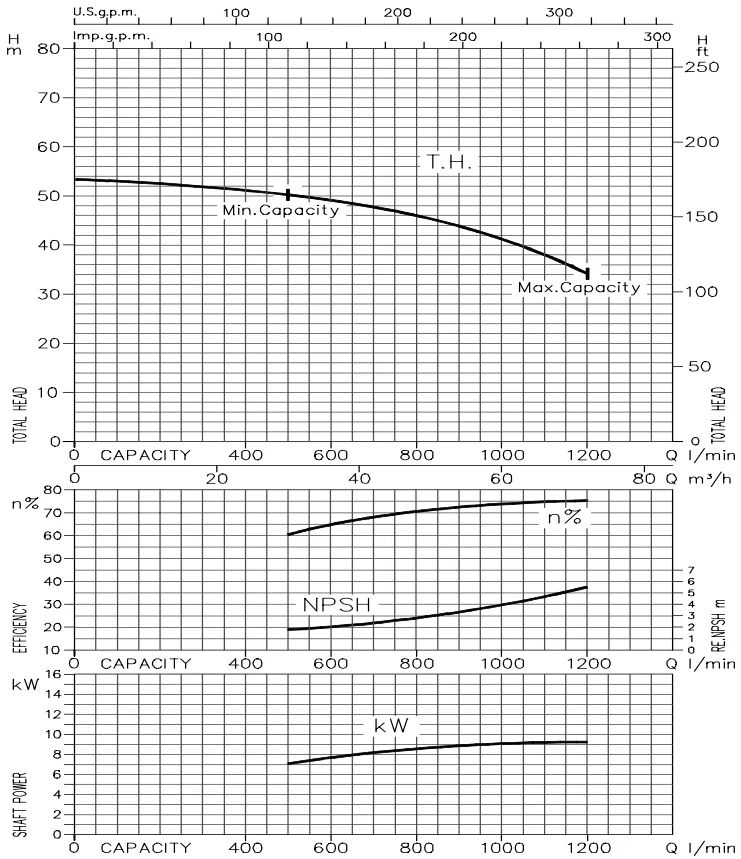

50-160/5.5 (5.5 kW) - Impeller diameter = 154

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

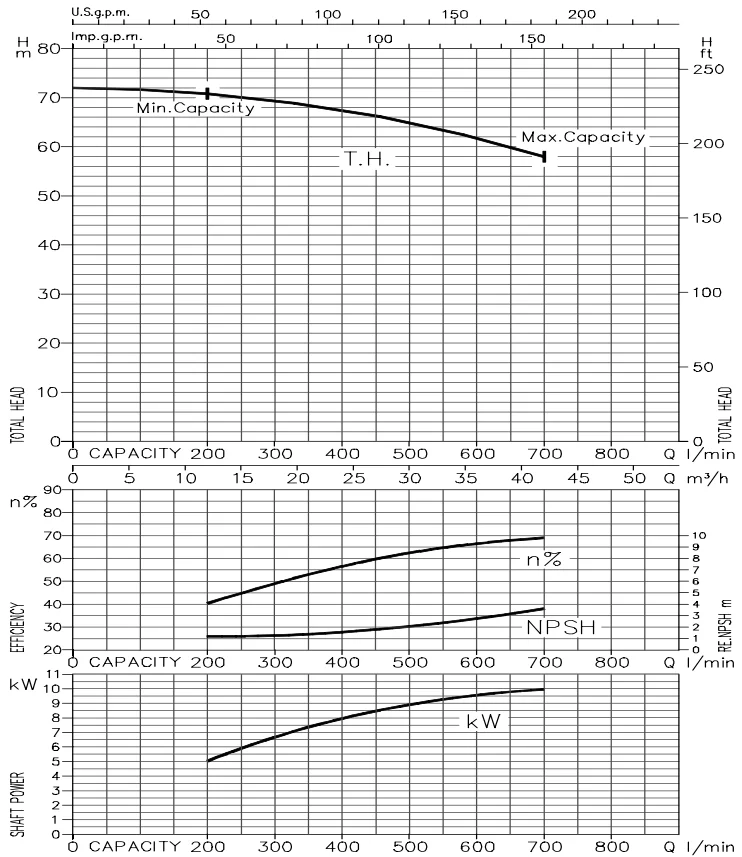

50-160/7.5 (7.5 kW) - Impeller diameter = 166

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

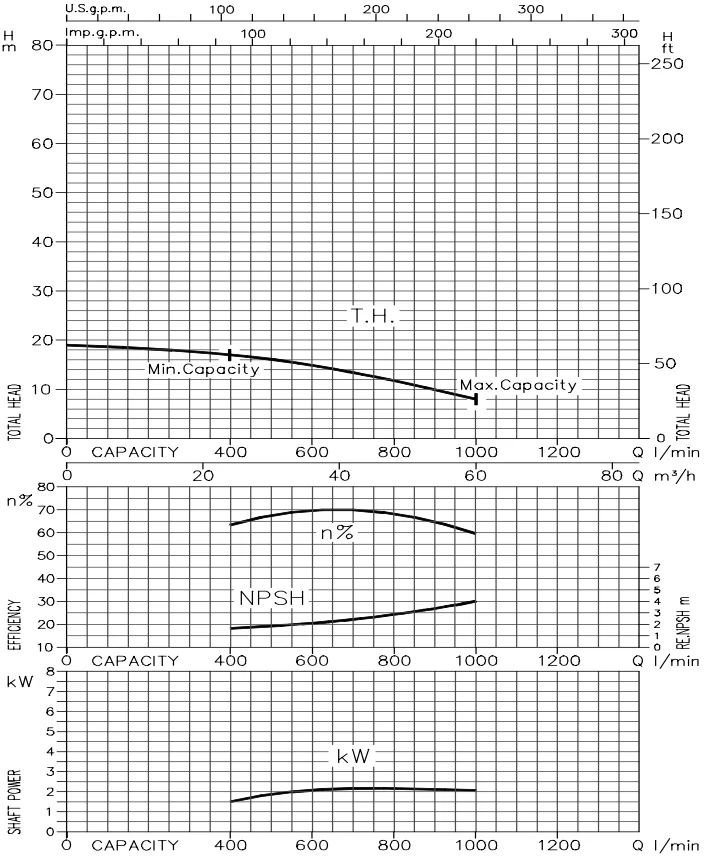

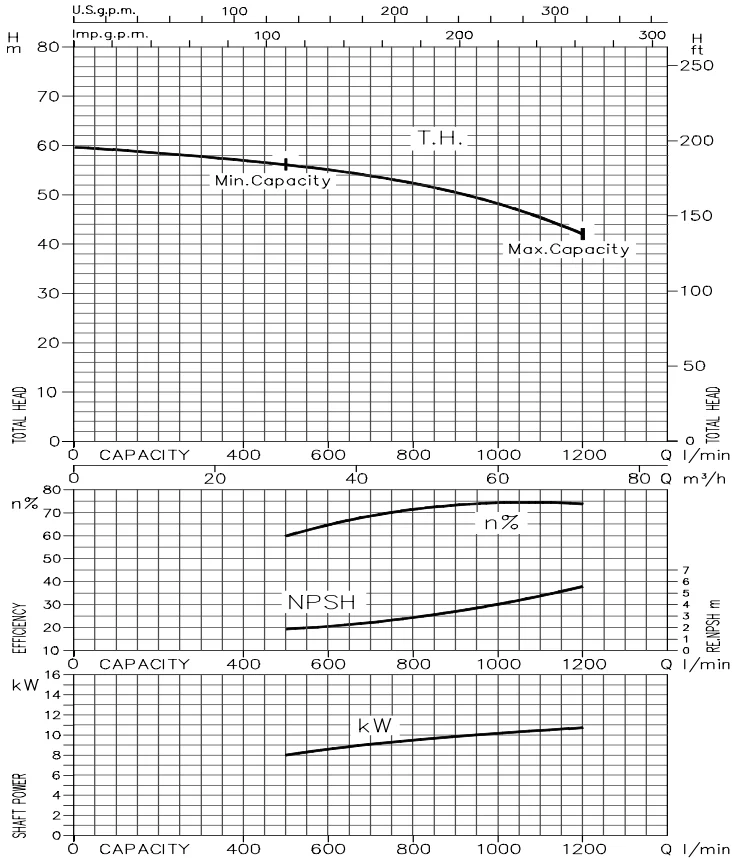

50-200/9.2 (9.2 kW) - Impeller diameter = 191

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

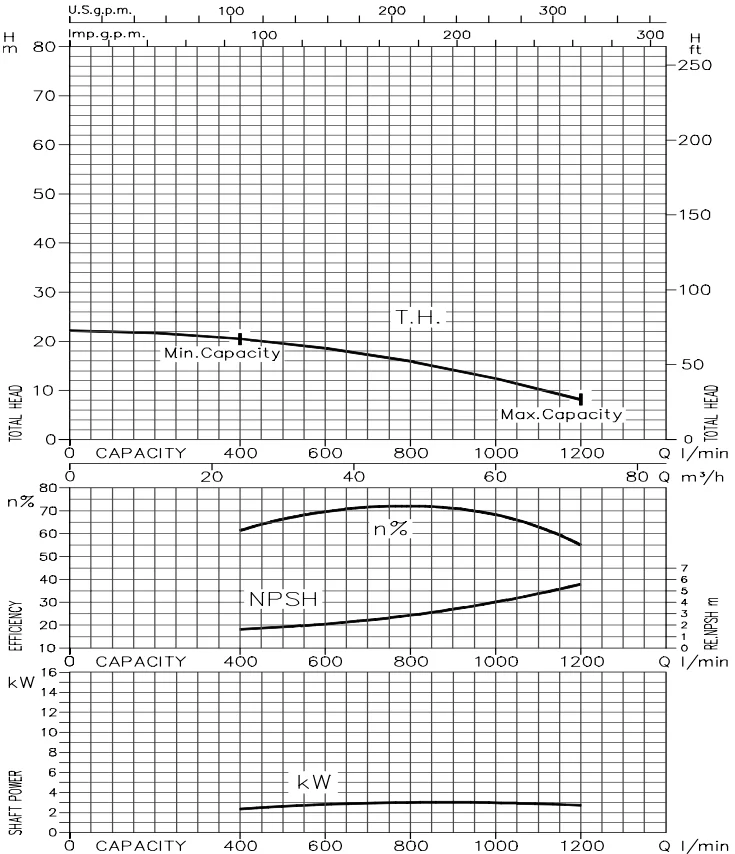

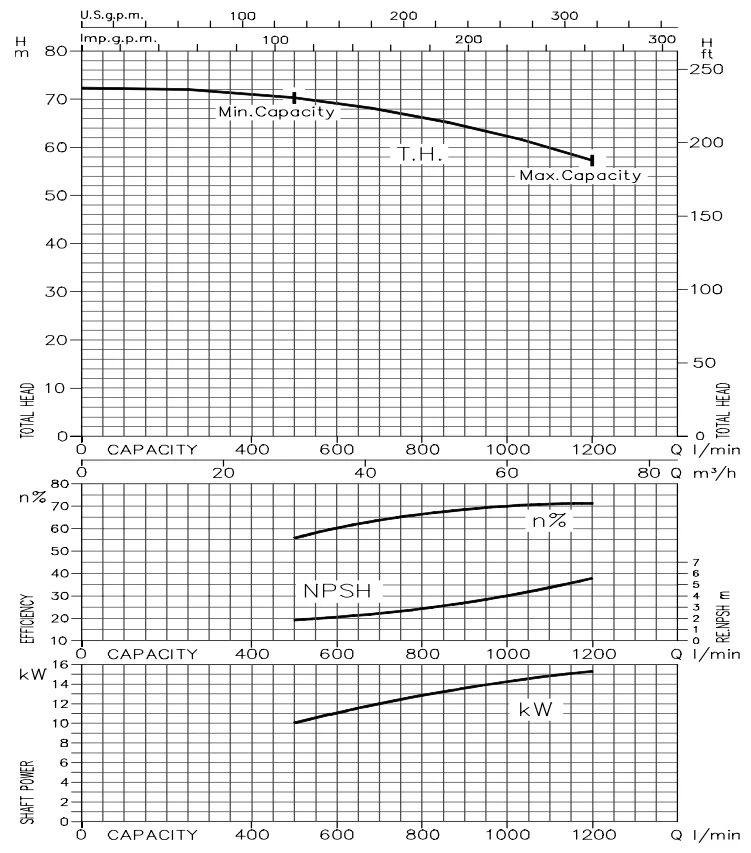

50-200/11 (11 kW) - Impeller diameter = 200

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A

50-200/15 (15 kW) - Impeller diameter = 224

Rotation speed: »2800 min-1 Test fluid: clean water at 20°C Applicable standard of test: ISO 9906 - Annex A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

LƯU Ý:

Sản phẩm Máy bơm ly tâm inox EBARA 3 Series 50Hz được phát triển liên tục, thông tin có thể có thay đổi mà không kịp thời thông báo đến Quý khách hàng!

Đánh giá sản phẩm của chúng tôi