MÁY ĐÁNH BÓNG CHỎM CẦU, THÂN TRỤ BỒN TANK INOX ĐƯỜNG KÍNH 6M

Application | ||||||||||||||||||||||||||||||||||||||||

| INM-JT-CZJ Tank & Dish end Polishing Machine This model can polish and grind for the different work piece of tank and grinding head through the different the grinding head of impeller then to meet the demand of polishing. The head polishing machine is extensive apply for the polishing of work piece in the range of medical, chemical, environmental purification, food and beverage, water filtration, etc. | |||||||||||||||||||||||||||||||||||||||

Product Features | ||||||||||||||||||||||||||||||||||||||||

1. The machine including head polishing, tank polishing, beam running system (up and down, left and right side), turntable of head work piece and the tank rotating frame. Main structure for welding structure and the electric controlling including control cabinet, frequency controller and motor. 2. A device to polish for the inside, outside and surface of tank and head, and equipped with two sets of grinding head, two sets of work piece rotary mechanism. 3. The machine can polish with automatic & reciprocating, do not read just the grinding head to polish, so it can ensure the polishing effect and consistency then to improve the work efficiency. 4. The machine can operate automatically with a default parameter for lots of work pieces polishing. The beam walks from the scheduled direction. The walking speed of beam from up to down and from left to right both according to the actual data in the panel. According to the grinding head floating technology, the grinding head close to the work piece's surface to grind uniformly when the machine is polishing, it is suitable for a small amount of work piece polishing. | ||||||||||||||||||||||||||||||||||||||||

Technical Parameters | ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

Equipment Main Structure | ||||||||||||||||||||||||||||||||||||||||

1. Cross hosts 1.1 Column2300mm, motorized beam3500mm, slide raising drive mechanism and other components. 1.2 Arm driven by a gear, rack and reducer; column driven by sprocket, chain and reducer. 1.3 Arm moving speed is adjustable frequency by variable-frequency drive. 2. Grinding head 2.1 Dish grinding head and tank grinding head are used for grinding and polishing dish on turntable and tank roller. 2.2 Adopts the technology of grinding head through a tracking of the whole air pressure to realize uniform polishing surface of the inside and outside. | ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

3. Tank roller 3.1 Frequency control, adjustable speed. 3.2 Two driving wheels, two driven wheels. 3.3 Roll size: different weight of tanks use different size 3.4 Multi-function adjustable roller table drives turbine worm reducer through one or two AC motors, with the reducer’s output end coaxial to the roller shaft (the shaft),thus realizing direct driving of the roller. The drive reducer is composed of cycloidal pin wheel speed reducer and fear reducer, which can ensure the longtime stable operation of work piece. | ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

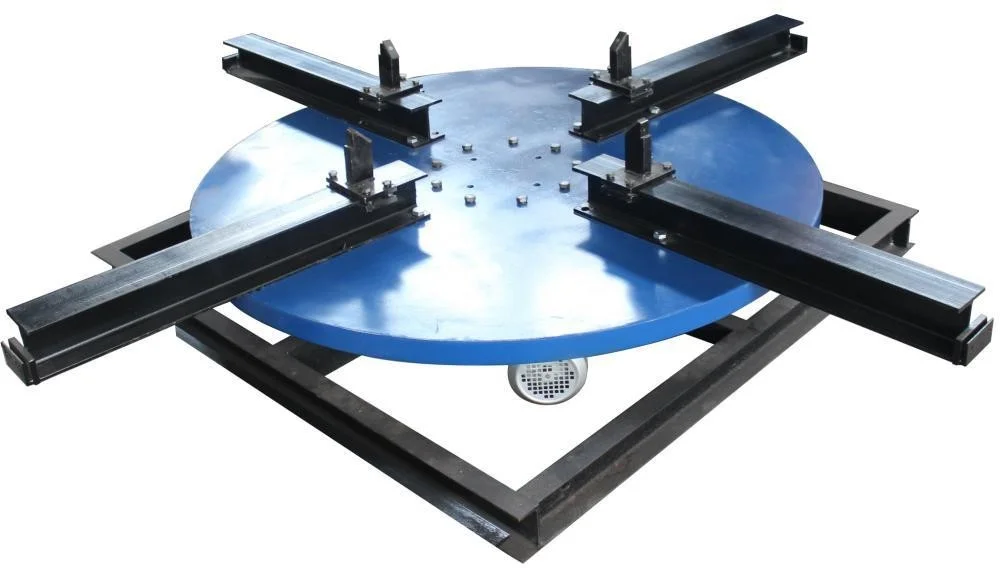

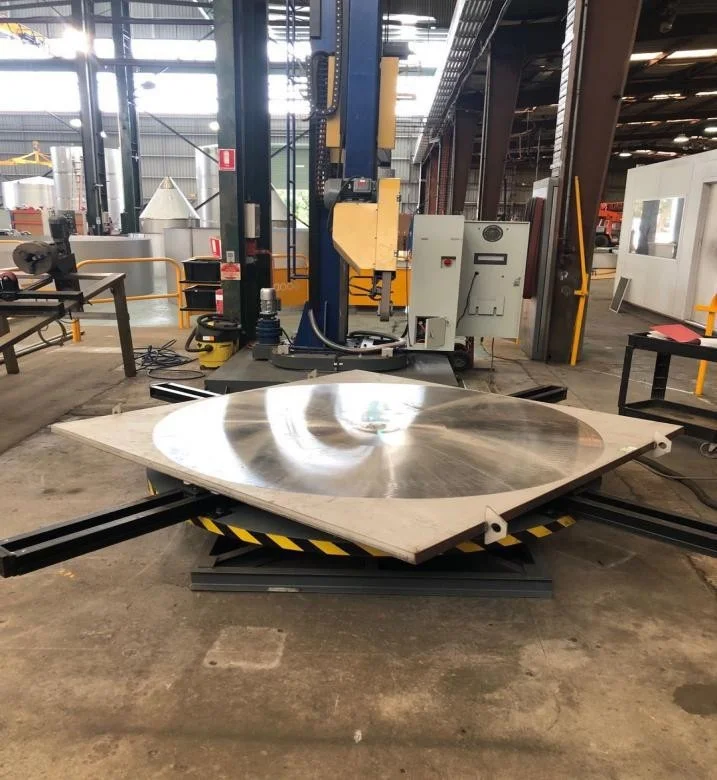

4. Turntable 4.1 Worktable revolution is based on step less speed regulation by transducer, featured by wide speed regulation range and stable operation. 4.2 The engine is a stock engine, four turning riding wheels are mounted in the base to support the gear ring, and slewing bearing, a professional carrying bearing, is adopted, with the turntable’s bearing capacity increased. 4.3 With high global stability, the device generally needn’t be fastened to foundation, so it’s easy to move and flexible to operate. 4.4 Driving roller seat drives speed reducer through AC brake motor, with the reducer’s output end coaxial to the driving axis(the reducer’s output shaft is hollow shaft),thus realizing direct driving of the roller table’s gear ring. | ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

5. Electric control system 5.1 Electric cabinet: operator station, actuators, control loop. Actuator including: contactors, relays, variable-frequency drive etc. 5.2 Pneumatic part: pressure gauges, cylinders, pipes and other components, to achieve the grinding head feed / return and adaptive constant floating structure. 5.3 Electric control system and pneumatic system installed in the same cabinet. | ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

Technical File Information and Installation | ||||||||||||||||||||||||||||||||||||||||

1. We provide structure diagram, electrical schematics (including wiring diagrams), spare parts lists, drawing for vulnerable parts. 2. The complete equipment will be assembled and tested at our factory before delivery. Before packing and delivery, we hope the equipment will be operated by your specialist technicians who will ensure that the equipment operates in full accordance with its specification in our factory. If you need our assembly and commissioning in your site, these services may be the subject of additional quotes. | ||||||||||||||||||||||||||||||||||||||||

To Be Supplied By The Customer | ||||||||||||||||||||||||||||||||||||||||

1. Site preparation (civil works) 2. 3Phase 3. air compressors 0.8mpa pipeline 6mm | ||||||||||||||||||||||||||||||||||||||||

Spare Parts | ||||||||||||||||||||||||||||||||||||||||

| | |||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

Machine Detail Photos | ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

In Malaysia INM-JT-CZJ heavy project- tank 9000mm diameter, 9000mm length, dished height-3000m | ||||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

In Turkey- Denizli INM-JT-CNC | ||||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

In Turkey-Sakarya INM-JT-CNC | ||||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

In USA, Russian, Portugal | ||||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

In Australia, Korea, India | ||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||

|  | |||||||||||||||||||||||||||||||||||||||

In Vietnam | ||||||||||||||||||||||||||||||||||||||||

| | |||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

In India | ||||||||||||||||||||||||||||||||||||||||

Lưu ý

Sản phẩm Máy đánh bóng được phát triển liên tục, thông tin có thể có thay đổi mà không kịp thời thông báo đến Quý khách hàng!

Đánh giá sản phẩm của chúng tôi