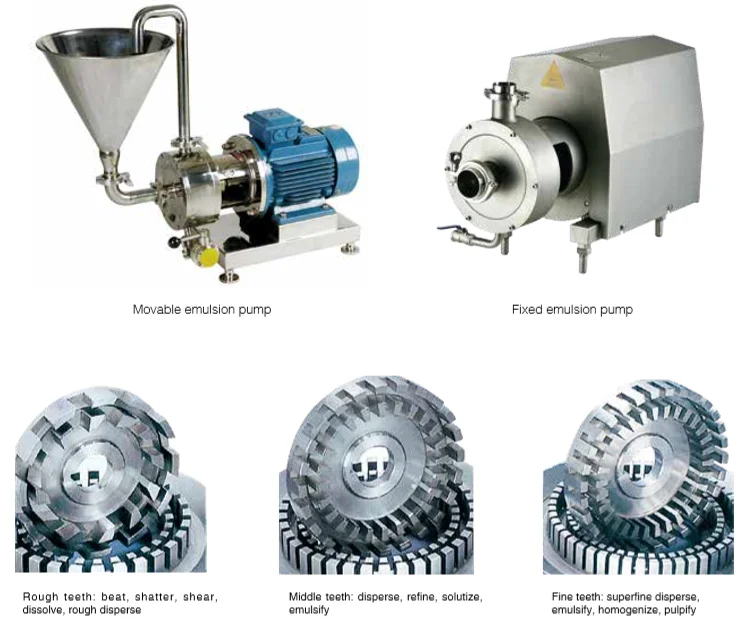

Máy khuấy tạo nhũ tương TRL-I Pipeline High Shear Dispersing Emulsifier

Operation Principle Pipeline high shear dispersing emulsifier is a high performance equipment used for continuous production or circulated treatment of fine material. In the small chamber, there are 1-3 sets of paired and clutched stators and rotor. Driven by motor, the rotor revolve quickly and produces a strong axial suctionforce which intakes the material to the chamber. The machine disperses, shears and emulsifiesthe material in shortest time, and the diameter range of the particles gets smaller so that fine and stable products are produced.

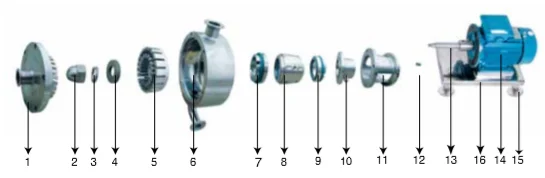

Rotor Pump installation Instruction

Note: The flow in the table refers to the data tested taking water as the medium. Outlet pressure of the listed type If circulated oricedure is adopted, intermittent high shear emilsiffer is recommended If there is high temperature, high pressure, flammable, explosive or corrosive condition, correct data should be provided by customers in order to customize the right product type For mediums that flow slowly, pumps of matched flow rate should be equipped in the inlet. The data in the tables is subject to change without notice. See the actual products for theright data. Advantages of pipeline high shear Dispersing Emulsifier Mass production suitable for continuous production of industrialized assembly line Small diameter range, and highly even Time saving, highly efficient and energy saving Low noise, stable operation Reduced quality difference between lots Material is fully dispersed and sheared Daliver in short with low lift Easy operation, convenient maintenance Automatic control | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TRL-I Pipeline High Shear Dispersing Emulsifier Pipeline High shear dispersing Emulsifier

1. Stator 2. Screw cap 3. Flexible gasket 4. Flat gasket 5. Rotor 6. Pump cavity 7. Mechanical seal (stationary ring) 8. Mechanical seal (moving ring) 9. Mechanical seal (stationary ring) 10. Seal cool seat 11. Pump seat 12. Pin 13. Pump shaft 14. Motor 15. Support 16. Frame Application

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

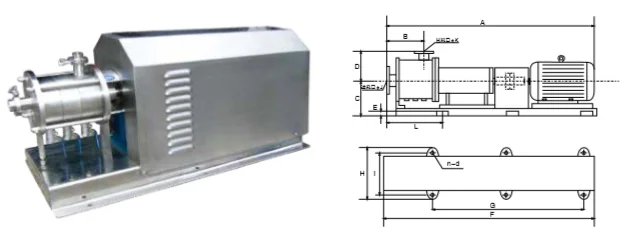

TRL-L3 Pipeline high Shear Dispersing Emulsifier

Operation Principle Three sets of stators are equipped in working cavity. Driving shaft in working cavity is an arm, electrical motor and the shaft in bearing cabinet can be connected by spiring coupling to improve the operation quality of driving shaft. Seal form can be selected in different conditions. It is fit for middle-large scale on –line continuous production or circulated treatment production process Main Parameter

Notes: Flow listed on the table refers to the data measured when the medium is water, the exit pressure of the model listed in the table In conditions high temperature, high pressure, flammability, explosion and erosion, relevant parameters must be provided clearly for selection customization precisely For poor liquid medium, a pump which has a matching flow is suggested to feed at the inlet input pressure If the data in the table is modified, no further notification will be given and the right parameters as per the provided sample. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

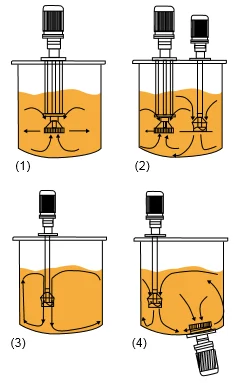

TRH Intermittent/Bottom-Mounted High Shear Dispersing Homogenizer

Operation Principle High shear dispersing emulsifier effectively, quickly and evenly disperse a phase or phases to another consecutive phase, usually, these phases are dissolvable to each other, The rotor revolves quickly and strong force is produced through high tangent speed and high frequency mechanical effect, the material in the narrow slotamong stator and rotor receives strong forces from mechanical and liquid shearing, centrifugal force, pressing, liquid fraction, clashing, tearing and rush water, the dissolvable solid, liquid and gas material is then istantly dispersed and emulsified evenly and finely with better production procedures and appropriate addictives and finally products with stable high quality are made. Advantages of pipeline High shear Dispersing Emulsifier Mass production suitable for continuous production of industrialized assembly line Small diameter range, and highly even Time saving, highly efficient and energy saving, highly even Low noise, stable operation Reduced quality difference between lots Material is fully dispersed and sheared Daliver in short distancc with low lift Easy operation, convenient maintenance Automatic control

|

LƯU Ý:

Sản phẩm Máy khuấy tạo nhũ tương được phát triển liên tục, thông tin có thể có thay đổi mà không kịp thời thông báo đến Quý khách hàng!

Đánh giá sản phẩm của chúng tôi