Mục lục

SH6000 SeriesSA Series Multi-Spring Pneumatic Diaphragm Actuator | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

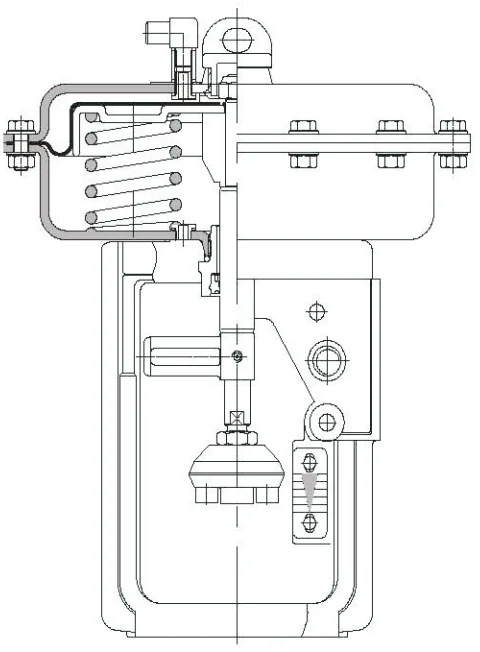

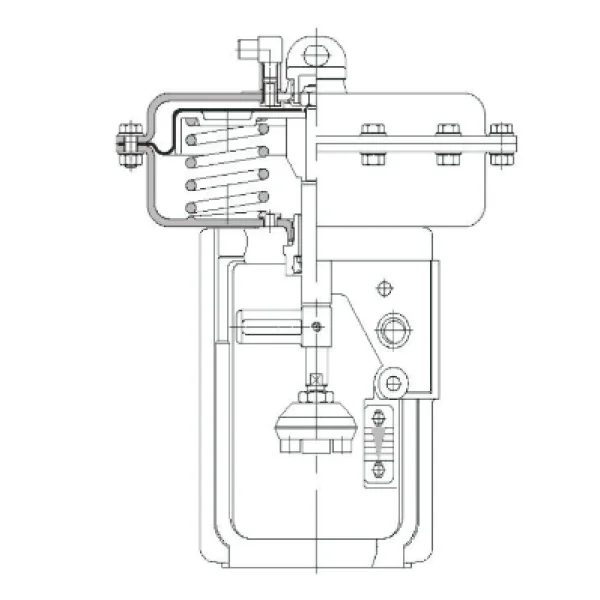

General SA series actuator is characterized by compact structure, pretty appearance and excellent capability. Max 0.6Mpa air supply can be forced to Powerful diaphragm, so the actuator presents bigger output thrust. The actuator is easily field reversible without the need of disassembly. The instrument air supply between positioner and actuator is attained through bores inside the yoke providing more reliability in comparison to conventional designs. This method ensures a safe air supply to the actuator and simplifies enormously the positioner mounting.

During operation there is a minimal overpressure against atmosphere on the backside of the spring chamber. This guarantees that no ambient air can be sucked in the spring chamber during stroke movement. The technique protects the essential inner parts against aggressive atmosphere, such as sea air, acidic air and so on.

|  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

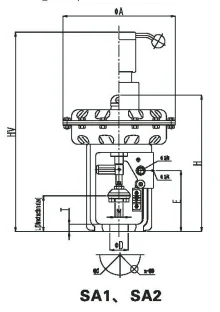

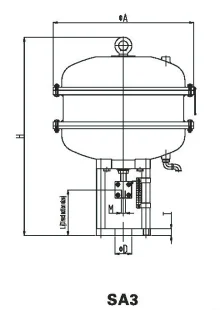

Type: SA series Size: f 270, f 400, f 596 Action : direct action SA1D, SA2D, SA3D Reverse action SA1R, SA2R, SA3R (Remark: 1 Direct action: signal increase to valve shut. 2 Reverse action: signal increase to valve open.) Materials Diaphragm casing : 20 Diaphragm : NBR + Nylon Actuator stem: 3Cr17NiMo ( 1.4122 ) Yoke : ZG25/ZG0Cr18Ni9 Special wiper ring: High quality polyurethane Painting: epoxy (china blue or other colours on request) Operation datum Supply: compressed air, nitrogen spring range: adapt to No. of springs. Ambient temp. : -20°C ~ +80°C and -20°C ~ +80°C optional Supply pressure: Max 0.6 Mpa Installation : best to install vertically Air connection: G1/8 (SA1), G1/4 (SA2), G3/4 (SA3) Accessories Positioner, Filter-regulator valve, Solenoid valve, limit switch, valve position transmitter, booster relay, Lock-valve, Handwheel, etc. Static error Hysteresis: ≤ 1% of FS with positioner ≤ 3% of FS with positioner Linearity: : ≤ ±1% of FS with positioner ≤ ±3% of FS with positioner (Remark: ablve error adapt to packing type) Relative parameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 1: SA1 parameter

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 2: SA2 parameter

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 3: SA3 parameter

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Size and Weight

Explanation of SA type notations | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Remark 1: Yoke SA1: 1----bolt impact type, connection size f40 2----bolt impact type, connection size f48 3----round nut impact type, connection size f48 4----round nut impact type, stainless steel yoke, connection size f48 5----round nut impact type, connection size f56 6----round nut impact type, connection size f40 7----round nut impact type stainless steel yoke, connection size f40 SA2: 1----round nut impact type, connection size f56 2----round nut impact type, connection size f72 SA3: 1----round nut impact type, connection size f72 2----round nut impact type, connection size f100 Remak 2: NO.of springs 2----two springs (SA3) 3----three springs (SA1, SA2) 4----four springs (SA3) 6----six springs (SA1, SA2, SA3) 8----eight springs (SA3) 9----nine springs (SA2) 0----twelve springs (SA2) Construction

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Construction | Inner supply protection type | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

· The actuator is easily field reversible without the need of disassembly. · Air to open with pipeless Air to close with external pipe. · Spray water proof · Corrosion resistant

| · The actuator is easily field reversible without the need of disassembly. · Air to open and air to close all with pipeless Springs are protected against aggressive atmosphere. · Spray water proof · Corrosion resistant | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

.PNG.webp) | · The actuator is easily field reversible without replacement of any parts · Rotation resistant structure can reduces abrasions of essential inner parts. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SA series characteristics |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

· Compact structure · Save air exhaust due to Smaller air chamber · Inner parts are protected against aggressive atmosphere · Soild cast steel yoke | · Convenient operation and rapid response. · Various types optional · Various materials optional · Various thrusts optional · High reliability and long lifetime. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ordering Information Please specify the following information: 1. Actuator Type (Size, Action, Yoke, Spring Nos., Designed form) 2. Air pressure supply 3. Travel 4. With handwheel or not (Top mounting) 5. Accessory (With positioner, pressure reducing valve or not) 6. Other special requests | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lưu ý

Sản phẩm Van điều khiển SA được phát triển liên tục, thông tin có thể có thay đổi mà không kịp thời thông báo đến Quý khách hàng!

.PNG.webp)

.PNG.webp)

Đánh giá sản phẩm của chúng tôi